Question # 1

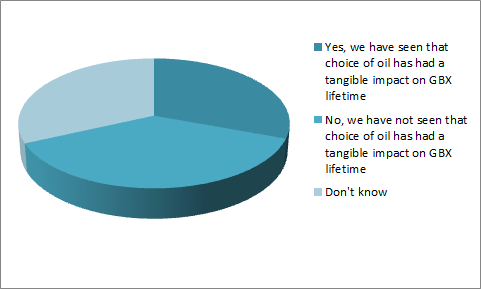

"Have you seen examples where the choice of oil has had a tangible impact on GBX lifetime and in which way did it have an impact?"

Suggestions from your peers, working for other wind asset owners around the world:

Please find longer answers than only "yes", "no" or "don't", below:

- Yes, in a lot of cases we can detect problems with oil degradation, water or contamination, where it may be the root cause of problems in gears.

- Not so far, due to our wind farms have been operating for 3 years only

- Yes. Viscosity, addatives and choice of mineral or synthetic

- Normally we use the oil delivered by the WTG OEM but we changed the oil sort because of foam and silted oil filter.

- No issues on our wind farms related to poor choice of oil.

- Yes, cupper corrosion

- yes, increasing failure rate of bearings

- Yes; we changed oil from Castrol A to X and filters got clogged very often.

- I've seen example of no-change-of-oil practice and no impact

- No big impact from oil itself but could be from additivs to oil

- SHC XMP 320 seems to "loose" yellow metal pasivator, which triggers cupper corosion in brass parts. Furthermore tar like deposits forms at particularly brass parts. The impact on life is not determined

- Yes, the viscosity index number was decreased

- Of course. The oil type is associated with the gearbox life time.

- No if the chemical analisys are comparable infact we decided to use the same oil for all our asset, instead some addictive in the oil could in some cases reduce the vibration parameters and prolong the life of the component

- Yes. Especially between mineral vs Synthetic

- Moving from mineral to synthetic has this benefit.

- No. Migration from mineral oils to synthetic oils but no specific impact on GBX lifetime?

- Yes, biogradable oil corroded GBX components

- Generally speaking a 320 cSt synthetic oil could be suitable

- Yes, basically the diference between an Esther and a PAO in regard the water ppm impact

- We know about the measures taken by Vestas relating to occurrences of elevated copper content in the oil, and dark deposits observed in some instances on brass components in gearboxes utilising the gear oil ‘Mobilgear™ SHC XMP 320’.

- Some gearbox lubrication systems are more sensive to foaming and excessive foaming can impact lifetime of the gearbox. Most common indication of the foaming is faulty oil level warnings.

- Yes, reduce degradation